Our Process

Harvest

Under the guidance of Alfredo “Ferruko” Perez Salinas, our lead Mezcal producer, we pick only the best and ripest wild maguey, a type of agave plant related to the blue agave used for tequila. Each plant is carefully grown with zero pesticides, insecticides, or harmful chemicals. It takes at least seven years for one plant to mature, so for every one we harvest, we plant 25 more.

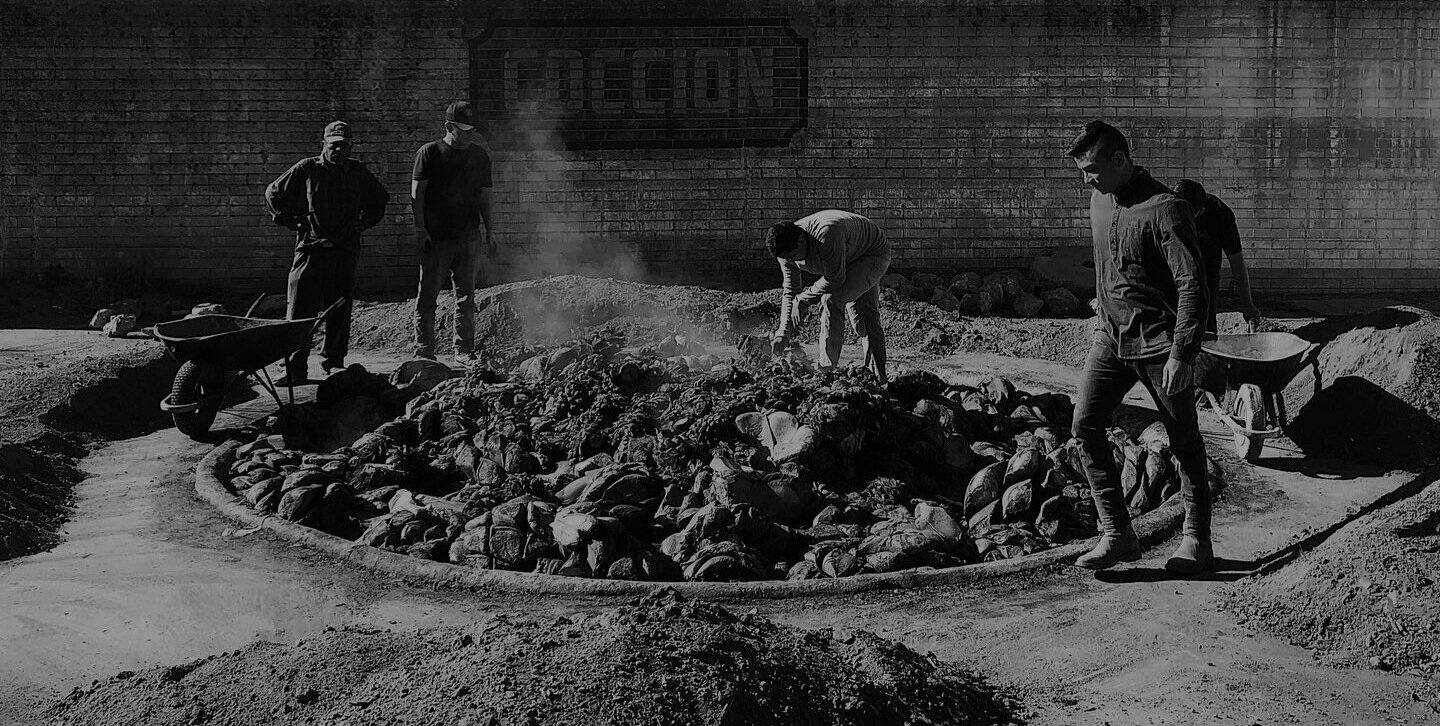

Cooking

Cooking maguey is a round-the-clock process that brings everyone from the ranch together. As the hearts of the maguey plants—called piñas—roast over wood, rocks, and earth, knowledge is shared and stories are told. We talk and laugh under the starry skies of the Tamaulipas desert, and then the fire pit is covered in canvas and soil and put to bed.

Milling

To mill the maguey, we use a traditional Egyptian traction mill called a tahona. Historically, the mill was powered by a team of horses, but our concern for the safety of animals inspired us to design a mechanical horse that turns our one-ton monolithic rock to crush the cooked maguey.

Fermenting

On the Rancho El Tinieblo, we ferment the mashed maguey for up to two weeks in our open-air wood vats. Then, with great care, we move the mash into casks one handful at a time. This process is very labor intensive, but it’s also the source of our mezcal’s complex flavor profile: roasted fruit, flowers, vegetation, and earth.

Distilling

We double distill our mezcal in copper stills over a wood fire. As an act of gratitude to Mother Nature, we let the first few drops of finished mezcal kiss the earth. It’s a ritual that goes all the way back to when the Spanish conquistadors first introduced this distillation process to the Mexican natives, who believed that mezcal purified the soul by ridding the body of evil spirits.

Bottling

The bottling process at El Tinieblo is as artisanal as the mezcal itself. Our bottles are made from recycled, hand-blown glass, and we use an authentic 1930’s printing press to stamp embossed logos onto 100% cotton paper labels. Each bottle is heat-closed by hand, and each label is numbered by batch, maguey type, and alcohol content.